Steel detailing

is a pivotal and multifarious step in the process of developing

anything made out of steel be it a basic building, modern plants,

spans, lifts, air dealing with units, and non-building structures. It

is an extremely basic process and requests intensive precision.

Structural steel detailing is an important and mandatory process in

all types of manufacturing and construction activities. The line of

process requires a number of following steps:-

-

The structural engineer and/or architect conceive an idea about a project and put it on paper in a general way. These drawings could also contain items linked to mechanical systems which pertain to the fabrication of the steel members.

-

Next in the detailing process, the steel detailer takes these design/ drawings and transforms them into meticulous diagrams for each steel piece.

-

The Detailer then produces drawings and plans for the making and erection of steel members such as beams, trusses, columns, braces, stairs and handrails, metal decking and joists etc.

With the ever-shifting market demand, the

need to stay ahead requires innovation and sustainable strategy. The

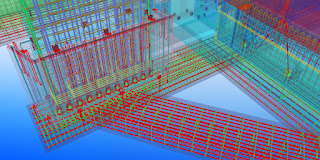

technologies used in CAD Steel

Detailing are computer- aided

design or CAD; earlier, manual drafting methods were used. The

process also involves 3D Modeling Technique which is an advanced

version of 2D drafting. 3D provides a better visualization and

insight into the project. 3D Modeling can be done with software like

X- Steel, AutoCAD and Microstation.

In steel detailing, the detailer’s

drawings covering the making of the steel pieces are called Shop

Drawings. They distinguish the exact particulars for creating every

part/bit of a structure. With steel detailing, once the steel

fabricator produces the steel members, the steel detailer steps in

again and produces the drawings for the erection of the steel members

in the field. These are called erection drawings.

It is the building site steel erector who

alludes to these illustrations in the steel enumerating process, so

as to know how and where to work with the created steel pieces.

Included in the erection drawings are dimensional plans to identify

the steel members, in addition to all work required on the site

including welding, bolting, and installing masonry anchors.

Structural Steel detailing high precision professional experts as these drawings must be able to

define and detail intricate tasks, the widespread usage of latest CAD

technologies and 3D software has improved the quality, speed, and

accuracy of structural steel detailing. It has made exact drawings in

3D format has become easy and affordable than complicated manual

detailing.

Structural Engineering Services has risen as a basic segment of open, business and mechanical

developments where steel components are overwhelming. Appropriate

from modern structures to private and shopping edifices, the

technique is broadly depended on design quick and mistake. Devoted

experts prepared in itemizing principles and CAD guarantees more

noteworthy accuracy and quicker finishing of basic steel specifying.

SteelConstruction Detailing understand

the essentials of healthy and perfect environment for living. We

provide all sorts of Steel Structural Engineering Services ;

we understand client’s need and prioritize the work accordingly. We

work on various sectors, from Structure to Architecture and

Mechanical to Electrical.