Before understanding the benefits of using Tekla for precast detailing, first, let us get a brief introduction to Tekla software and what it offers.

What is Tekla Software?

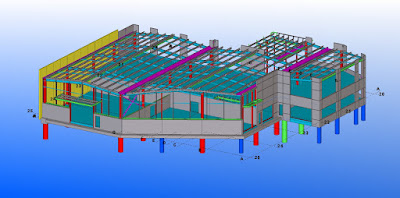

Tekla is a BIM software used for building steel and concrete structures. It incorporates the features of 3D modeling for engineers. In the construction industry, it is used for structural steel detailing and precast concrete detailing. It guides structural engineers from concept through fabrication for steel and concrete structures. It automizes the process of creating shop drawings.

Tekla supports the creation of models for structural steel, concrete, rebar, and miscellaneous steel. It is, in fact, specifically designed to be used for steel and concrete. Till date engineers have used this software for building skyscrapers, bridges, residencies, factories, plants, offshore plants and model stadiums.

What Tekla offers?

Now that we are through with the concept of Tekla, let’s see what it has to offer in the construction industry:

• With the use of Tekla, one can build any structure regardless of material and size.

• Detect clashes early in the fabrication process and avoid it beforehand.

• Get precise drawings and reports from the model.

• Streamline the workflow with approved standards.

Let’s dig deep into this and understand the major role of Tekla in precast detailing:

• Error-free precast concrete detailing:

Errors in detailing leads to inaccurate information which is the cause for an increased cost. Rework is done leading to wastage of material and time. When working with Tekla, one can identify and detect clashes earlier before fabrication process actually begins with models created. Hence, it reduces on-site problems and reworks.

Tekla models include all the information for generating drawings, reports, and other fabrication data. This reduces the chances of human errors as changes can be automatically updated through these models. Hence, information remains consistent. This ultimately improves collaboration between design, factory and site teams.

• Virtual Building:

Tekla precast concrete detailing allows a direct interaction with building information models. This gives the benefit of intelligent and accurate connections to make sure everything fits in together well.

Tekla comes with a predefined set of special tools for precast industry. It offers 3D components for building quality information models. This 3D visualization optimizes the way designs are communicated to the clients. It also allows automatic creation of bills for materials, bar bending schedules, and other reports. Changes can be easily updated and communicated.

• Option for Customization:

One can create custom tools using Tekla for structural steel detailing ensuring intelligent connections, reinforcements and model components. This customization is also applicable to fabrication reports and erection drawings. One can also share, update and manage tools customized for the company with the team.

• Easy Sharing:

Tekla allows sharing same models from anywhere, anytime regardless of the internet speed. This enhances collaboration between the teams.

We are offering Tekla services:

Steel Construction Detailing Pvt. Ltd. is offering Tekla precast panel detailing with improved efficiency and quality. Our structural steel detailing services are provided by expert detailers so as to minimize the risks of failure. We abide by the standards and codes followed by the construction industry.